Organic Materials & fiber Engineering, Chonbuk National University

Graduate School will introduce.

-

Carbon Neutrality Composites Lab

Carbon Neutrality Composites Lab- Professor : Kim, Seong Yun Professor

- Phone : 063.270 2336

- E-mail : sykim82@jbnu.ac.kr

- Laboratory : technical Building 2, room 109

Research field

Lightweight materials for future mobility

- Polyproylene self-reinforced composites via chemically 100% single polymer based strategy

- High-pressure resin transfer molding based carbon fiber reinforced composites

Functional materials for electrical car

- Material extinguisher concept introduced self-reinforced composites

- High impact resistance of carbon fiber reinforced composites via incorporating pore preserved silica aerogel

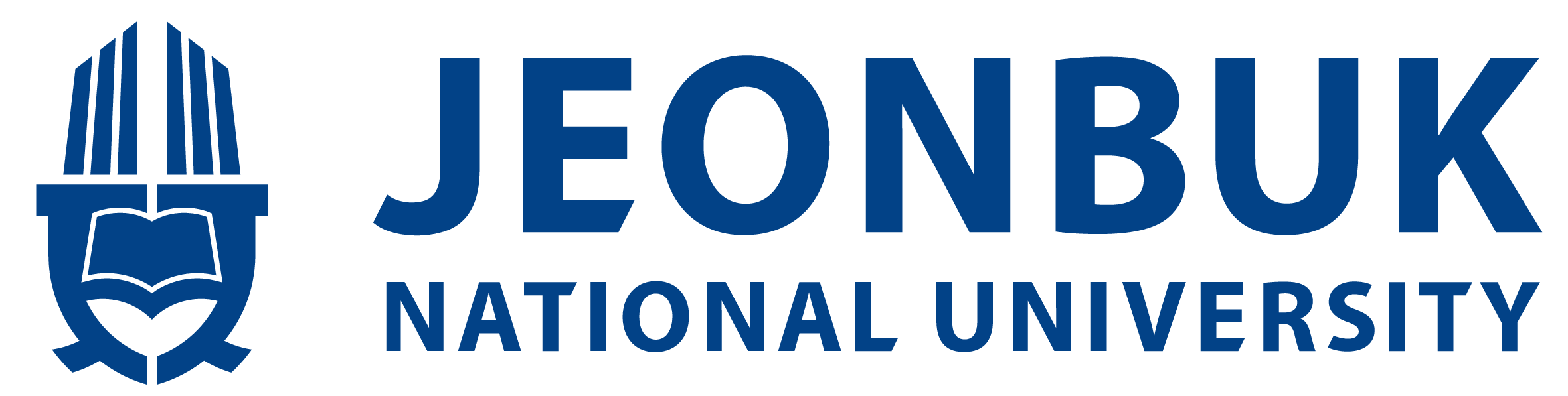

Key materials for self driving

- Polyproylene self-reinforced composites via chemically 100% single polymer based strategy

- High-pressure resin transfer molding based carbon fiber reinforced composites.

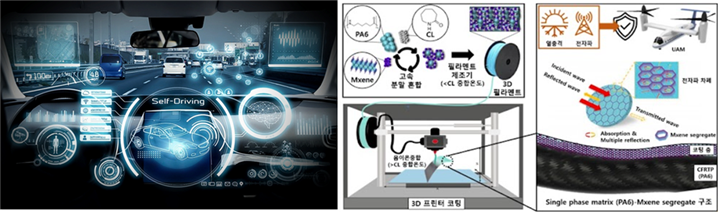

Nano-energy generator for harvesting renewable energy

- Material extinguisher concept introduced self-reinforced composites

- High impact resistance of carbon fiber reinforced composites via incorporating pore preserved silica aerogel

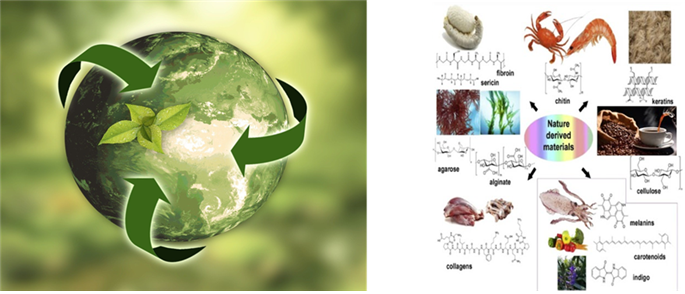

Natural resources for eco-friendly upcycling

- Waste spent coffee ground for electromagnetic shielding/thermal insulation/heating element